China High Quality Mb Series Stepless Transmission Supplier – P series high precision planetary reducer – YEXIN

China High Quality Mb Series Stepless Transmission Supplier – P series high precision planetary reducer – YEXIN Detail:

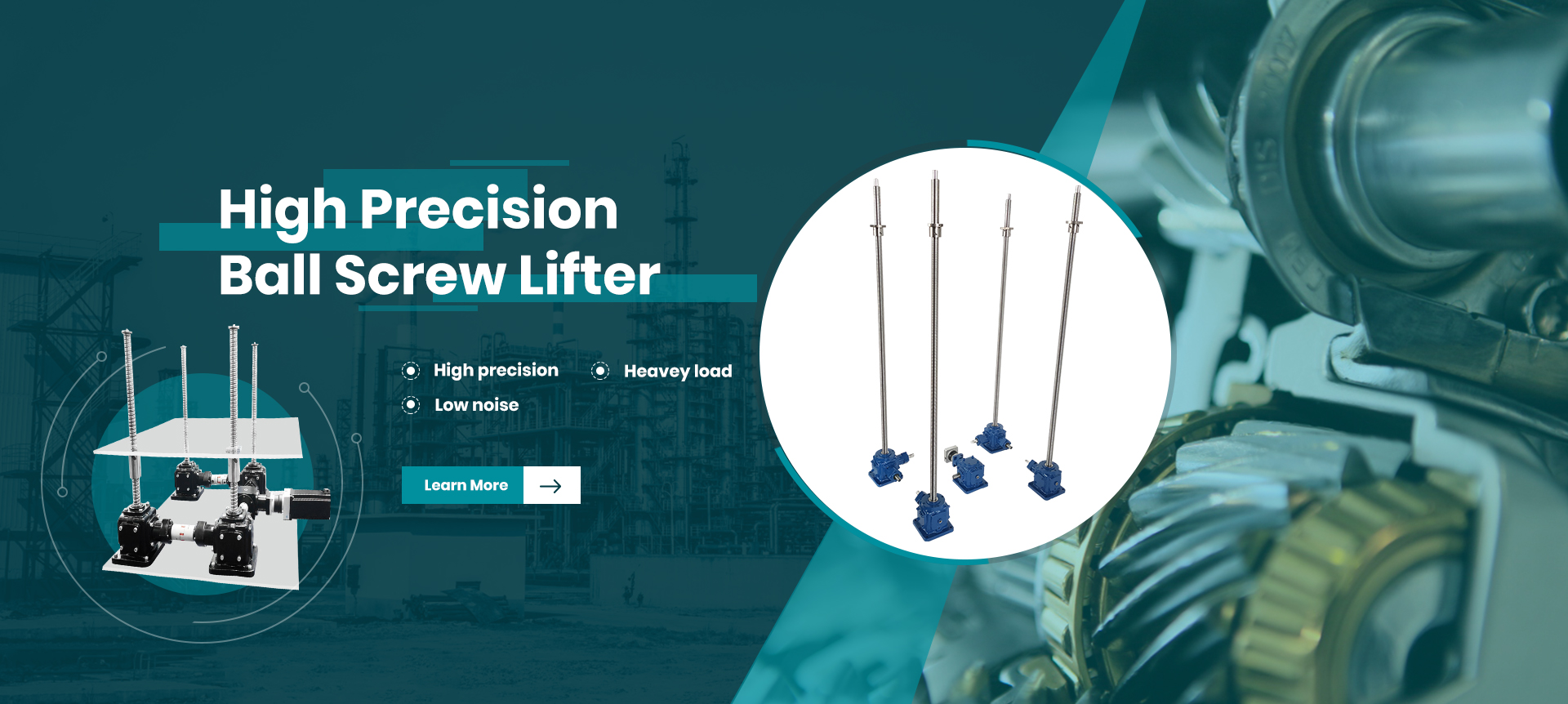

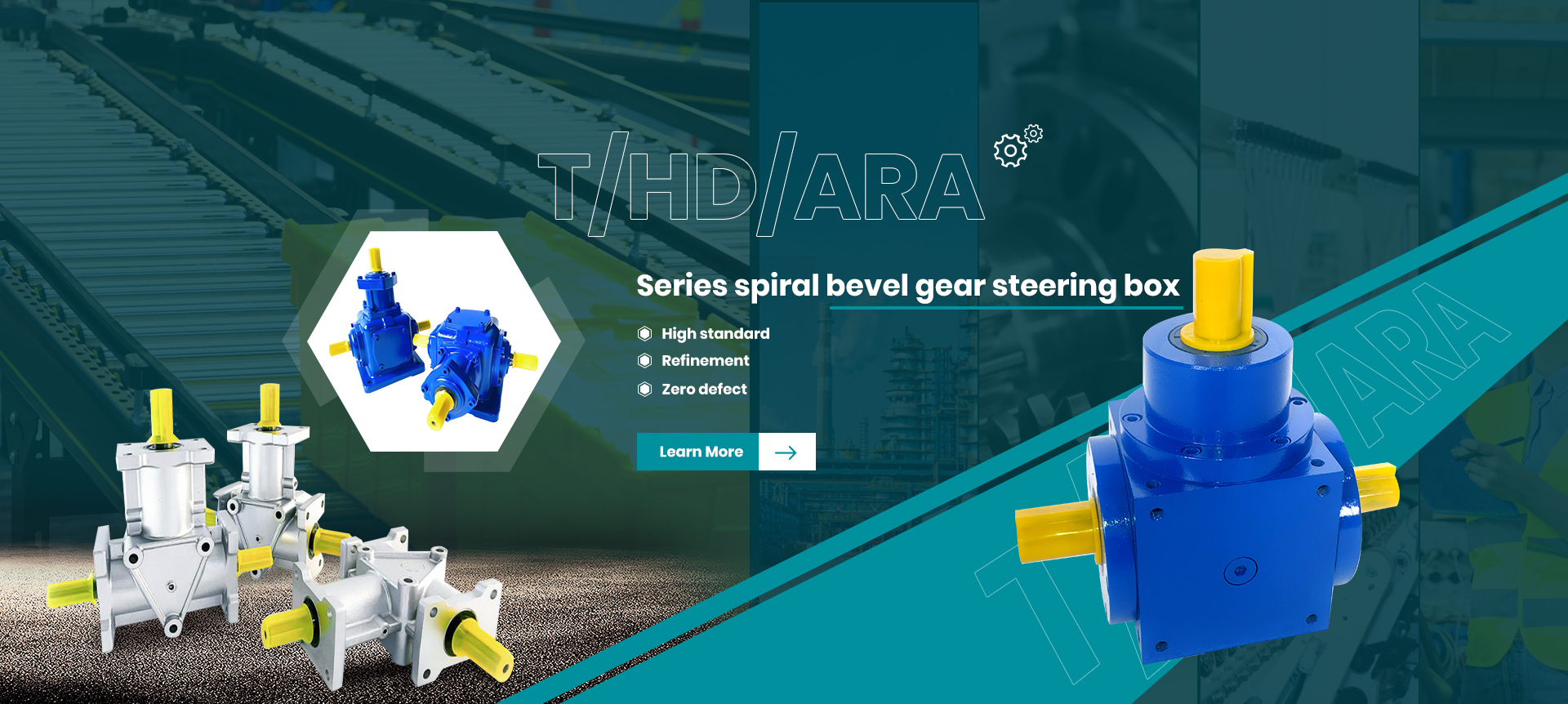

P series high-precision planetary reducer, servo planetary reducer is another name for planetary reducer in the industry. Its main transmission structure is: planetary gear, sun gear and inner ring gear. Compared with other reducers, the servo planetary reducer has the characteristics of high rigidity, high precision (within 1 point in a single stage), high transmission efficiency (97% – 98% in a single stage), high torque / volume ratio, lifelong maintenance free, etc. Most of them are installed on stepping motor and servo motor to reduce speed, increase torque and match inertia.

For structural reasons, the minimum single-stage deceleration is 3, and the maximum is generally no more than 10. The common deceleration is: 3.4.5.7.10,15,20,25,30,35,40,50,70,80100. Generally, the number of reducer stages does not exceed three-stage deceleration, but some large reducers have four-stage deceleration compared with customized reducers. The maximum rated input speed of the servo planetary reducer can reach 18000rpm (related to the size of the reducer itself. The larger the reducer, the smaller the rated input speed). The output torque of the industrial servo planetary reducer generally does not exceed 2000Nm, and the special Super torque servo planetary reducer can reach more than 10000nm The working temperature is generally about – 25 ℃ to 100 ℃, and its working temperature can be changed by changing the grease.

P series high precision planetary reducer, servo planetary reducer series: it has the characteristics of high precision, high rigidity, high load, high efficiency, high speed ratio, high service life, low inertia, low vibration, low noise, low temperature rise, beautiful appearance, light and small structure, convenient installation, accurate positioning and so on.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for China High Quality Mb Series Stepless Transmission Supplier – P series high precision planetary reducer – YEXIN , The product will supply to all over the world, such as: Peru, Amman, Grenada, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!