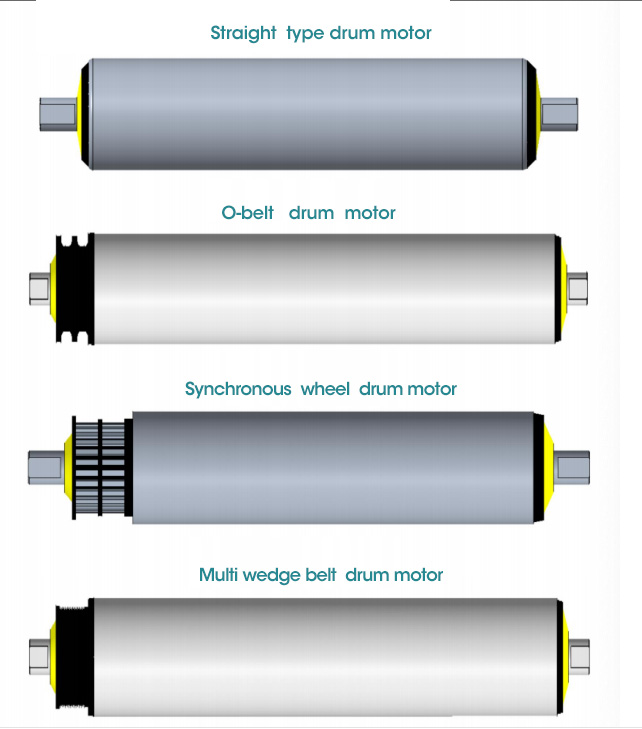

BLD DC brushless electric roller

|

1 |

Comanpy YJ Motor |

|

|

2 |

Model&Dimension |

|

|

Motor type |

BL |

|

|

Brushless motor |

||

|

3 |

T: Carbon steel pipe (which) Drum material S: 304 Stainless steel pipe |

|

|

4 |

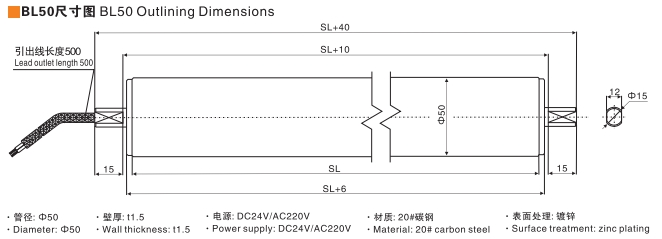

Drum diameter 50mm (Example) 50: Drum diameter 50mm |

|

|

5 |

Drum shape |

A: cylindrical tube |

|

6 |

Linear speed ( 25m/min (Example) 25: Rotary line speed 25m/min |

|

|

7 |

Drum length (Example) 400: Total length 400mm (not included) |

|

|

8 |

Rated power ( (Example) 40: Motor rated power 40W |

|

|

9 |

Voltage type |

D: DC power supply 1: Single phase AC |

|

10 |

Voltage (Example) 24:24V |

|

|

11 |

Lead wire type |

Vacancy representation (which) |

|

Rated power (continuous) |

W |

10 |

|||

|

Rated speed |

r/min |

3000 |

|||

|

Rated torque |

N.m |

0.032 |

|||

|

Instantaneous maximum torque |

N.m |

0.048 |

|||

|

Speed control range |

RPM |

200-3000 |

|||

|

Speed control range |

On load |

Below ± 1%: condition 0-rated torque, rated speed, rated voltage, room temperature |

|||

|

On voltage |

Below + 1%: condition rated voltage +10%, rated speed, rated load, room temperature |

||||

|

On temperature |

Below ± 1 %: Conditions of ambient temperature 0~+40oC rated voltage, rated load and rated speed |

||||

|

Power input |

Rated voltage V |

/ | / | 24VDC Optional 36VDCJ48VDC) |

|||

|

Voltage tolerance range |

±10% |

||||

|

Frequency Hz |

/ |

/ |

|||

|

Frequency tolerance range |

/ |

/ |

|||

|

Rated input current A |

/ |

/ |

0.7 |

||

|

Instantaneous maximum input current |

A |

/ |

/ |

1.4 |

|

External diameter drum motor (DC Power Supply When Applied To24VDC/36VDC/48VDC}

|

Rated power (continuous) |

W |

40 |

|

|

Rated speed |

r/min |

3000 |

|

|

Rated torque |

N.m |

0.127 |

|

|

Instantaneous maximum torque |

N.m |

0.191 |

|

|

Speed control range |

RPM |

200-2500 |

|

|

Speed control range |

On load |

Below ± 1%: condition 0-rated torque, rated speed, rated voltage, room temperature |

|

|

On voltage |

Below + 1%: condition rated voltage +10%, rated speed, rated load, room temperature |

||

|

On temperature |

Below ± 1 %: Conditions of ambient temperature 0~+40oC rated voltage, rated load and rated speed |

||

|

Rated power (continuous) |

W |

40 |

|||

|

Rated speed |

r/min |

3000 |

|||

|

Rated torque |

N.m |

0.127 |

|||

|

Instantaneous maximum torque |

N.m |

0.191 |

|||

|

Speed control range |

RPM |

200-2500 |

|||

|

Speed control range |

On load |

Below ± 1%: condition 0-rated torque, rated speed, rated voltage, room temperature |

|||

|

On voltage |

Below + 1%: condition rated voltage +10%, rated speed, rated load, room temperature |

||||

|

On temperature |

Below ± 1 %: Conditions of ambient temperature 0~+40oC rated voltage, rated load and rated speed |

||||

|

Power input |

Rated voltage V |

/ | / | 24VDC Optional 36VDCJ48VDC) |

|||

|

Voltage tolerance range |

±10% |

||||

|

Frequency Hz |

50/60 |

/ |

|||

|

Frequency tolerance range |

±5% |

/ |

|||

|

Rated input current A A |

0.72 |

0.36 |

2.70 |

||

|

Instantaneous maximum input current |

A |

1.4 |

0.55 |

5.60 |

|

Brushless motor continues to set speed and a feedback signal are compared from the speed of the motor to adjust the voltage applied to the motor; therefore, even if the load change, still can set the speed from slow instantaneous adjustment to, and in order to stabilize the running speed. Three phase induction motor with inverter control is not feedback control, so the load becomes larger, the speed will be greatly

reduced; for the high speed stability requirements, it is recommended to use brushless motor.

|

Rated Power P W |

Gear Box Series |

Reduction Ratio i |

V Max Speed V m/min |

Rated Speed n RPM |

Allowable Torque T Nm |

Driving Force F N |

L Length L mm |

|

40W |

One Stage |

3.65 |

129 |

821.9 |

0.420 |

16.80 |

N260~800 |

|

5.36 |

88.0 |

559.7 |

0.610 |

24.40 |

|||

|

6.55 |

72.0 |

458.0 |

0.750 |

30.00 |

|||

|

8.63 |

54.6 |

347.6 |

0.990 |

39.60 |

|||

|

Two Stage |

13.53 |

35.0 |

221.7 |

1.390 |

55.60 |

2270~800 |

|

|

18.92 |

25.0 |

158.6 |

1.950 |

78.00 |

|||

|

24.65 |

19.0 |

121.7 |

2.540 |

101.6 |

|||

|

28.05 |

16.8 |

106.9 |

2.890 |

115.6 |

|||

|

33.92 |

14.0 |

88.40 |

3.500 |

140.0 |

|||

|

44.69 |

10.5 |

67.10 |

4.610 |

184.4 |

|||

|

58.22 |

8.00 |

51.50 |

6.000 |

240.0 |

|||

|

Three Stage |

67.08 |

7.00 |

44.70 |

6.240 |

249.6 |

N290~800 |

|

|

81.11 |

5.80 |

37.00 |

7.540 |

301.6 |

|||

|

91.36 |

5.00 |

32.80 |

8.490 |

339.6 |

|||

|

102.88 |

4.60 |

29.20 |

9.560 |

382.4 |

|||

|

118.98 |

4.00 |

25.20 |

11.06 |

442.4 |

|||

|

145.36 |

3.20 |

20.60 |

13.51 |

540.4 |

|||

|

165.64 |

2.80 |

18.10 |

15.00 |

600.0 |

|||

|

231.61 |

2.00 |

12.90 |

15.00 |

600.0 |

|||

|

301.68 |

1.50 |

9.900 |

15.00 |

600.0 |

The permanent magnet is used in the rotor of the brushless motor, which can reduce the secondary loss of the rotor. Therefore, compared with the three-phase induction motor with frequency conversion, the power consumption is reduced by more than 20%, which is conducive to energy saving.